Crest Hellcat in the Real World

May 19, 2023

By: Dan Chudecke

For over a decade, the Lochinvar CREST has been an efficient and reliable source of hydronic heat. The product line has been improved over the years to take advantage of new technologies and components.

The latest Crest innovation is the Hellcat Combustion Technology system that continuously adjusts based on real time O2 data to improve operation (aka O2 trim). A common challenge for peak condensing boiler operation is maintaining the proper fuel-to-air ratio, especially considering the wide range of ambient conditions we experience. Excess oxygen in natural gas and liquified Propane combustion prevents a boiler from condensing and capturing 10-12% of energy an owner paid for. Some systems just accept a certain amount of variability in operation. However, if a boiler is to constantly maintain peak performance, the adage of “measure to manage” must be applied. Unlike very large industrial boilers, no cost-effective opportunity for adaptation and improvement existed for smaller commercial-sized systems until now.

Given that heating plants are a CRITICAL system in our region, Mulcahy will only recommend products and options to our customers that operate reliably with minimal attention. In the past, O2 trim systems required frequent sensor replacement and testing. Lochinvar engineers set out to create a system that provided efficient operation but not at the cost of excessive maintenance. A recent visit to a Hellcat installed in the fall of 2021 proved that they were successful.

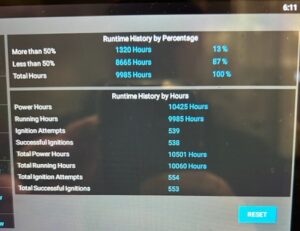

There is a significant amount of data logging functions inherent to the standard Crest boilers (both with and without Hellcat). A good indicator of proper operation after a system has been online for a while is comparing run times and cycles. Long average run times are good to see and can only happen if all the control elements are properly set for the system. On this project, the boilers operated approximately 18 hours per successful ignition. It would likely have been longer if not for the code requirement that boilers cycle off at least once every 24 hours to test the controls. (See Figure 1)

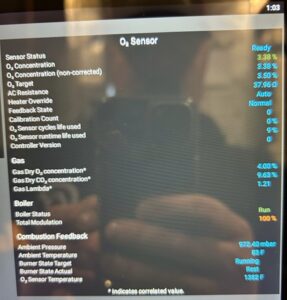

Another piece of data available on Hellcat units is the is how much life remains on the O2 sensor. At this installation, only 9% of the sensor’s life had been used over two full winters. (See Figure 2). It will be years of operation before the sensor will need service.

There is no better test of a product than the real world and the Lochinvar Crest with Hellcat Combustion Technology has met the challenge. For more information contact Mulcahy Company for any questions.

Figure 1

Figure 2